-

FAST SHIPPING

FAST SHIPPING

-

COMPETITIVE PRICE

COMPETITIVE PRICE

-

EXCELLENT AFTER-SERVICE

EXCELLENT AFTER-SERVICE

BOS-B Pro-A3 vs BOS-B: What Deye’s latest rack changes for small-scale C&I storage

Feb 19,2026Solar energy grants in Catalonia: practical guide (2026)

Feb 16,2026Île-de-France Solar Incentives: Grants, VAT 5.5%, Steps

Feb 12,2026Solar Energy Grants in Andalusia 2026: A Practical Guide

Feb 06,2026What Size Solar Panel to Charge a 12V Battery (Wattage Guide)

Jan 30,2026BOS-B Pro-A3 vs BOS-B: What Deye’s latest rack changes for small-scale C&I storage

A closer look at module chemistry, system architecture and deployment trade-offs for 100 kW to 2.5 MW projects in Europe.

Uniz Solar | Technical Briefing | 18 February 2026

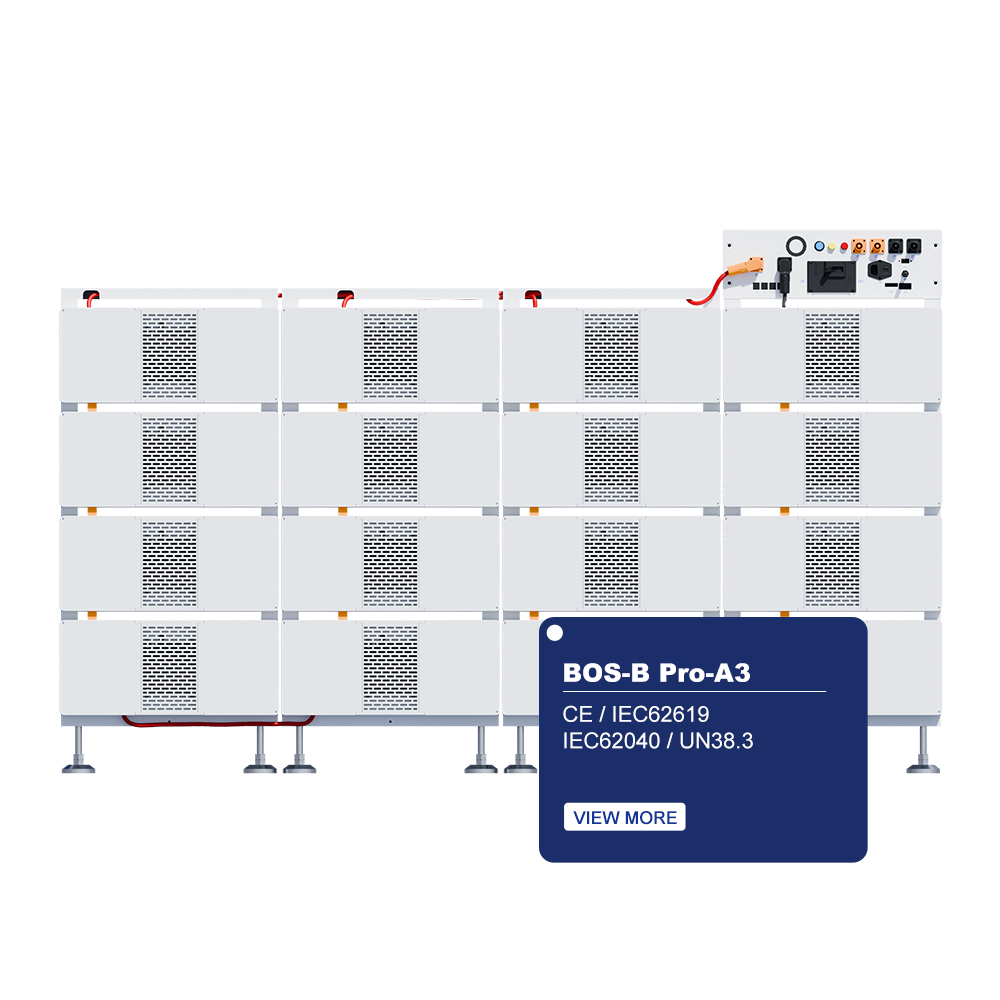

Figure 1. Deye BOS-B Pro-A3 rack (illustrative image).

Across Europe, commercial and industrial (C&I) sites are using batteries less as a “backup box” and more as an operational asset: shaving peaks, shifting energy into cheaper tariff windows, and stabilising power for critical loads. The system design decisions that mattered five years ago - shipping weight, wiring time, and how cleanly the storage layer talks to power conversion - now show up directly in project timelines and service costs.

Deye’s BOS-B has been a familiar reference point in this segment: a high-voltage, rack-mounted LFP platform used to build scalable clusters around a 100 kW to multi-megawatt PCS. The new BOS-B Pro-A3 keeps that overall philosophy, but shifts several important numbers and, more importantly, the way integrators can compose a system around the battery.

Both BOS-B and BOS-B Pro-A3 are modular, rack-mounted lithium iron phosphate (LFP) systems intended for small-scale C&I energy storage. They share the same basic logic - build a high-voltage string from 51.2 V modules, manage the string via BMS, and expand capacity by paralleling racks - but they are optimised for slightly different priorities.

In Deye’s published specifications, BOS-B is a 215 kWh class rack (214.5 kWh nominal, 193.05 kWh usable at the recommended 90% depth of discharge). BOS-B Pro-A3 moves that up to a 257 kWh class rack (257.23 kWh nominal, 231.51 kWh usable at the same 90% recommendation).

The headline change is energy density at the rack level. BOS-B Pro-A3 uses larger 16.08 kWh battery modules (51.2 V, 314 Ah), compared with 14.3 kWh modules (51.2 V, 280 Ah) in BOS-B. On paper that delivers roughly 20% more energy per rack before any changes in footprint or electrical integration are considered.

The Pro-A3 also increases the rack’s charge/discharge current rating to 180 A (from 168 A in BOS-B). That extra headroom is not a dramatic jump, but it can be valuable in systems that spend long hours cycling near their power limits - particularly where the PCS is sized aggressively for peak shaving or rapid tariff response.

Deye’s documentation also describes a broader “matching mode” range for Pro-A3: module quantity in series is optional from 5 to 16, and Deye provides explicit guidance on how many modules to use for on-grid, off-grid and PV-coupled configurations. In practice this makes Pro-A3 easier to tune around PCS operating windows and PV string design, rather than forcing the design to fit a fixed string length.

BOS-B remains a straightforward, proven building block. Its 15-module series configuration (768 V nominal) is clean to design around, and its electrical and environmental limits are well understood by installers who have already delivered projects on the platform.

The key point is that “older” does not mean “obsolete”. BOS-B still carries the same core compliance set (CE, IEC 62619, IEC 62040 and UN 38.3), the same recommended 90% depth of discharge, and the same 10-year warranty position in Deye’s C&I literature. For projects where design risk is a bigger concern than maximising rack-level energy, BOS-B can remain the sensible choice.

A battery rack rarely lives alone. What matters to most EPCs is the amount of auxiliary hardware required to turn a rack into a working system: switching between grid and backup sources, PV integration, metering, and the control layer that enforces export limits or time-of-use behaviour.

Deye positions Pro-A3 inside a modular “C&I ESS solution” built from a 100/125 kW PCS module, an 8-MPPT PV module (200 kW PV access power, 160 kW PV input power) and a 500 kW static transfer switch (STS). In Deye’s spec tables, the PCS supports up to 20 units in parallel (system power up to 2.5 MW), while the STS is rated at 500 kW and is designed to coordinate grid, load and generator ports with a sub-10 ms switching time. The practical outcome is a kit-of-parts approach: a site can start at 100 kW and expand to the megawatt range with repeatable blocks rather than bespoke cabinets.

BOS-B is also used in Deye’s C&I solution materials, but Pro-A3 is the rack explicitly specified at 257 kWh, 314 Ah and with the more flexible series-count guidance. For integrators building PV + storage or generator-backed microgrids, that configuration guidance is often the difference between a “works on paper” design and one that starts reliably in the field.

The unglamorous details are often the ones that decide whether a fleet is profitable to service.

Both racks provide an LCD state-of-charge and fault-code display and support TCP/RS485/CAN communications. Both specify smart fan cooling, broad discharge temperature tolerance (-20 to 55°C), and the same enclosure rating (IP20). From a commissioning standpoint, the workflow is familiar.

Where Pro-A3 feels more modern is in its system-level packaging. Deye’s Pro-A3 manual describes the rack as a repeatable assembly built around a high-voltage control box (1000 V / 180 A) and standardised 16.08 kWh modules. Deye’s internal launch material emphasises that a “truly modular” design is intended to reduce transport and assembly effort by eliminating non-essential equipment - a claim that will resonate most with installers who have spent days customising cabinets on site.

The figures below are taken from Deye’s published technical specification tables. They are intended as a practical snapshot for early-stage design; always confirm the final configuration during engineering.

|

Parameter |

BOS-B Pro-A3 |

BOS-B |

|

Battery module energy |

16.08 kWh |

14.3 kWh |

|

Battery module nominal voltage |

51.2 V |

51.2 V |

|

Battery module capacity |

314 Ah |

280 Ah |

|

Battery modules per series string |

5-16 (optional, by application) |

15 (fixed) |

|

Max. system nominal voltage |

819.2 V |

768 V |

|

Max. system energy (nominal) |

257.23 kWh |

214.5 kWh |

|

Max. system usable energy |

231.51 kWh |

193.05 kWh |

|

Max. charge/discharge current |

180 A |

168 A |

|

Recommended depth of discharge |

90% |

90% |

|

Operating temperature (charge / discharge) |

0 to 55°C / -20 to 55°C |

0 to 55°C / -20 to 55°C |

|

Communication interfaces |

TCP / RS485 / CAN |

TCP / RS485 / CAN |

|

Enclosure IP rating |

IP20 |

IP20 |

|

Rack dimensions (W x H x D) |

2150 x 1305 x 800 mm |

2150 x 1136 x 800 mm |

|

Rack weight (approx.) |

2240 kg |

1944 kg |

|

Warranty (as stated in Deye C&I literature) |

10 years |

10 years |

|

Certifications (as stated) |

CE / IEC 62619 / IEC 62040 / UN 38.3 |

CE / IEC 62619 / IEC 62040 / UN 38.3 |

#Deye #EnergyStorage #BESS #HybridESS #CommercialESS #CAndIStorage #SolarStorage #PVSystem #Microgrid #EnergyManagement #PeakShaving #LoadShifting #BackupPower #GridSupport #IEC62619 #UN383

+31610999937

+31610999937 [email protected]

[email protected] De Werf 11, 2544 EH The Hague, The Nederland.

De Werf 11, 2544 EH The Hague, The Nederland. WhatsApp: +1 (917) 257 2995/

WhatsApp: +1 (917) 257 2995/Copyright © 2023 Uni Z International B.V. VAT: NL864303440B01 All Rights Reserved