-

FAST SHIPPING

FAST SHIPPING

-

COMPETITIVE PRICE

COMPETITIVE PRICE

-

EXCELLENT AFTER-SERVICE

EXCELLENT AFTER-SERVICE

Solar energy grants in Catalonia: practical guide (2026)

Feb 16,2026Île-de-France Solar Incentives: Grants, VAT 5.5%, Steps

Feb 12,2026Solar Energy Grants in Andalusia 2026: A Practical Guide

Feb 06,2026What Size Solar Panel to Charge a 12V Battery (Wattage Guide)

Jan 30,2026Solar Panel to Accumulator Ratio: Size PV and Batteries Right

Jan 23,2026

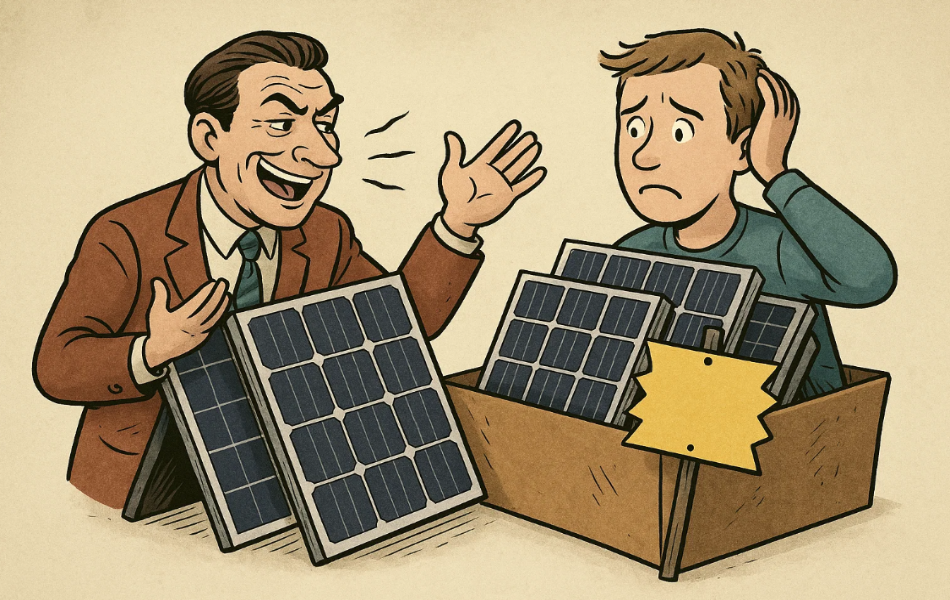

Scammers sell panels labeled "new" that are actually refurbished, cracked, or severely degraded. Common tactics include falsified paperwork, relabeled serial numbers, withheld return windows, or demonstrating power output under unrealistic laboratory conditions (unstable irradiance, short test time). Knowing the common tricks helps you spot red flags before you hand over money.

Good paperwork reduces risk. Ask for: original invoice (date, seller, model), manufacturer serial number, datasheet for that model (STC values), warranty/registration documents, and any repair records. Use the serial number to cross-check with the manufacturer's support (phone/email) to confirm production date and warranty status. If the seller refuses to provide serials or produces blurred/altered images, treat that as a major red flag.

A careful visual inspection catches many problems that refurbishing can hide. Don’t skip this step — it’s fast and effective.

Look for microcracks, large cell fractures, browning or hotspots, delamination (separation between glass and encapsulant), and mismatched cell coloring. Small scratches are normal; internal cracks or dark spiderweb patterns are not.

Check for burned/bubbled backsheet material, repaired frames, or evidence of water ingress. Corroded clamp points or bent frames indicate prior damage or poor handling.

Open the junction box (if the seller allows) and inspect diode condition, solder joints, and cable strain relief. Loose or re-soldered connections are common in refurbished panels and can fail soon after installation.

A combination of simple on-site tests and more advanced measurements gives a reliable picture of the panel’s true condition. Below are practical tests ranked by the equipment needed and the information they provide.

| Test | What it shows | Equipment / skill |

| Open-circuit voltage (Voc) & short-circuit current (Isc) | Basic functional check and big power issues | Multimeter; easy |

| IV curve under known irradiance | Accurate estimate of max power and fill factor; detects hidden degradation | IV tracer or module tester; moderate skill |

| Thermal imaging (operating) | Shows hotspots, mismatch, bypass diode failures | Infrared camera or FLIR phone add-on; basic to moderate |

| Insulation resistance / wet leakage | Detects moisture ingress and backsheet failures | Megohmmeter; moderate |

| Electroluminescence (EL) imaging | Reveals microcracks and cell defects not visible to eye | EL tester / professional lab; advanced |

Do this test on a clear, sunny day around solar noon for best comparability. If you cannot arrange ideal conditions, record irradiance, cell temperature, and time — these let you normalize results to STC.

Manufacturers quote power at Standard Test Conditions (STC): 1000 W/m² irradiance and 25°C cell temperature. If your test irradiance is lower or cell temperature higher, adjust expected power roughly linearly for irradiance and apply temperature coefficient for temperature effect.

Quick formula (approximate): Pstc ≈ Pmeas × (1000 / G) × exp[−γ × (Tcell − 25)], where G is measured irradiance (W/m²) and γ is the panel's temperature coefficient in %/°C (use −0.3%/°C as typical for many panels). This gives a ballpark for comparing to the rated Pmax.

Acceptable degradation depends on cost and planned lifetime. New panels typically degrade ≈0.5–0.8% per year. A used panel with 10%–15% degradation may be reasonable if price reflects remaining life and warranty. Anything over ~20% reduction in rated power should trigger caution unless the price is very low and you need short-term power.

For multi-panel purchases or rooftop removals, hire a certified PV technician. Professionals can produce reliable IV curves, EL imaging, insulation tests, and full condition reports. Their report can be used to negotiate price or for warranty transfer requests.

Use this short template when messaging a seller — it sets clear expectations and gives you documentation to rely on later.

A simple pricing approach: start with current new price for the same model (or closest equivalent), then discount for age, measured degradation, lack of transferable warranty, and visible damage. Example buckets:

Do not buy sight-unseen. Always get serial numbers and do at least Voc/Isc or a normalized Pmax check in sunlight. Prefer sellers who allow on-site testing, provide clear paperwork, and agree to a short conditional return period (48–72 hours) after installation if the panel underperforms. For bulk buys, insist on professional IV and EL reports.

| Tool | Use | Typical cost |

| Multimeter | Voc / Isc check | $20–$100 |

| Pyranometer / reference cell | Irradiance measurement | $200–$1,000 |

| IV tracer / module tester | Full IV curve & Pmax | $1,000–$6,000 (rental cheaper) |

| Thermal camera | Hotspot detection | $200 (phone addon)–$3,000 |

Compared with new products, second-hand panels often come with uncertain quality, hidden performance risks, and limited or no after-sales support. If you are not deeply familiar with panel testing or have higher reliability requirements, we strongly recommend choosing brand-new products for guaranteed performance and long-term peace of mind.As an authorized distributor, we offer competitively priced, brand-new solar panels from leading mainstream brands.

←

How to Build a Solar Farm: Requirements, Costs & Risks

→

Photovoltaic Accessory Guide — Selection, Installation, Maintenance

+31610999937

+31610999937 [email protected]

[email protected] De Werf 11, 2544 EH The Hague, The Nederland.

De Werf 11, 2544 EH The Hague, The Nederland. WhatsApp: +1 (917) 257 2995/

WhatsApp: +1 (917) 257 2995/Copyright © 2023 Uni Z International B.V. VAT: NL864303440B01 All Rights Reserved